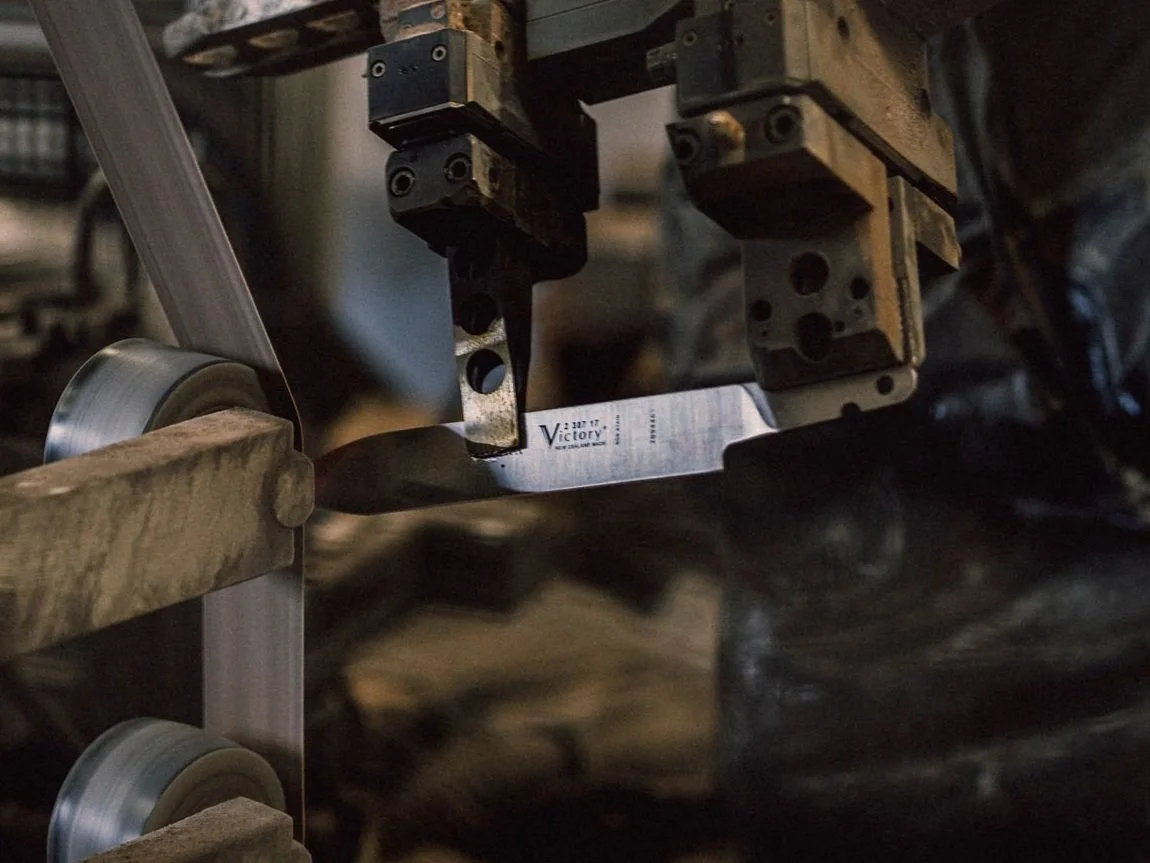

MEMBER SPOTLIGHT: Victory Knives - New Zealand Made Since 1927

Victory Knives have a proud heritage stretching back to 1927. All major meat and fish processing companies in New Zealand and Australia use their knives. Victory Knives continues to thrive today by maintaining the highest standards in manufacture and materials, building its reputation for unsurpassed quality. Importing German steel and ensuring their heat-treatment and processing is world class.

We spoke to their managing director, Gareth Hughes, to learn more about Victory Knives and its long history of supplying the butchery industry.

1. Can you tell us about the history of Victory Knives?

Victory Knives has been proudly making knives in Auckland for 98 years. Founded by Edward Goddard in 1927 to supply butchers, the company shifted focus during World War II to provide knives for the New Zealand, Australian and U.S. armies. After the war, Victory Knives returned to its butchery roots and has since expanded to serve multiple industries, including meat and fish processing, produce, aquaculture, commercial diving, as well as general customers.

2. Victory Knives has been a trusted name in the industry for years – what do you think has contributed to that success?

Consistency is key. Our success comes down to delivering reliable, high-quality knives that meet the needs of our customers. Providing a product that performs well and offers great value keeps our customers coming back.

3. What makes your knives stand out from others on the market?

In many processes, we have maintained the same approach for years, kind of like making Nana's old cake recipe. The main thing that makes our knives stand out is what our loyal customers have to say about them. Being a small, family-run business, we have close relationships with our customers and pride ourselves on listening to them.

4. How do your knives support butchers and meat processors in their daily work?

Our knives are essential to meat processing in New Zealand, used by everyone from large-scale processors to independent butchers. They are at the heart of what we do, and we take pride in providing tools that support efficiency and precision. I’m also a strong supporter of young butchers entering the trade and honing their craft.

5. What are some key trends you’re seeing in butchery tools and equipment?

Given the long history of this great trade, there has been a series of improvements made to the knife shapes and styles to help with various parts of the process over the years. Our mantra is that we make them for the professionals, so we are always seeking continuous improvement to make their job easier by working directly with them.

6. What are some of your most popular knife models for butchers?

The 5-inch and 6-inch boning knives, along with the larger steak and breaking knives, are the general go-to for butchers.

7. Do you offer any special services, such as sharpening or custom engraving?

We can do custom engraving on larger run orders, and all of our knives come with a lifetime guarantee (excluding misuse and general wear and tear).

8. What is your top tip for maintaining and extending the life of a good butcher’s knife?

Butchers will know this. Steeling your knife regularly is the number one rule. It's also important to use the right knife for the right job.

9. What is the most rewarding part of supplying knives to the industry?

Being part of a key process in the food chain, without a knife, it is very difficult to get a steak on a plate.